Aly Virani explains how the support from Crown Dental Burs has helped to elevate his dentistry and make a difference to patient care.

Who are you, where are you based and what type of dentistry does your practice offer?

For three years I have had a practice in Cardiff where I am clinical director and my clinical work is limited to implants.

Part of my role is, therefore, to make decisions that maintain and ideally improve the clinical standards within the entire practice. We made the decision early on to make patient care our priority.

Therefore, our equipment, protocols, appointment times, patient journey, materials and staff training are of a standard that we would consider ideal if we were the patient.

Our patients understand why we are not competing on price with others in our area but choose to come to us for quality and our referrers have also come to expect the same.

This puts a lot of pressure on me (and the entire team) to ensure that we are constantly striving for improvement.

How did you discover Crown Dental Burs Ltd?

I met Paul at the ADI congress last year and loved his approach and the quality of his products when I tried them on the trade stands.

Since then, my practice orders exclusively from him and he has provided me with so many solutions that I didn’t realise I needed! Sadly burs are an aspect of dentistry that is poorly taught and understood.

They are the most used consumables in restorative dentistry and beyond, but we tend to see all burs as the same – their shape, coarseness and band colours – and their price. So we work in or own practices that order the cheapest available option from our suppliers.

As associates, we either go through lots of burs or constantly fight with blunt burs. Our handpieces get leaned on and are always being sent off for expensive repairs.

We blame this on the temperamental handpieces rather than the fact that we are using the equivalent of wooden barrels instead of tyres on our cars. Of course we are going to have problems.

The quality of burs complements the quality of our electric handpieces. From a business and patient experience point of view, sub-standard burs represent false economy.

However taking it one step further, burs can contribute to the ease with which we perform clinical procedures. In Paul we have found someone that we can approach with a problem and he is incredible at helping us to find solutions.

Each individual in our team, including clinicians and nurses, have Paul’s number and communicate with him regularly to find these solutions. Can’t cut a material efficiently? Hard to access area? Difficulty maintaining standardised bur boxed following sterilisation? Paul is our man.

What products have you purchased?

All of our surgical and restorative Burs as well as our microsurgery instruments and kits come from Crown Dental Burs. We started off by ordering a few burs to try them out and never looked back.

Most recently I tried out the Coricama surgical instruments that Paul supplies. I was blown away by his approach and the quality of the instruments. Paul came to watch a surgery and suggested solutions and alternative instruments that I hadn’t considered.

Not only is he careful about only supplying the quality of products that he is happy to put his name on, but his relationship with his customers seems to be solution based. He has set the standard for how we work with suppliers.

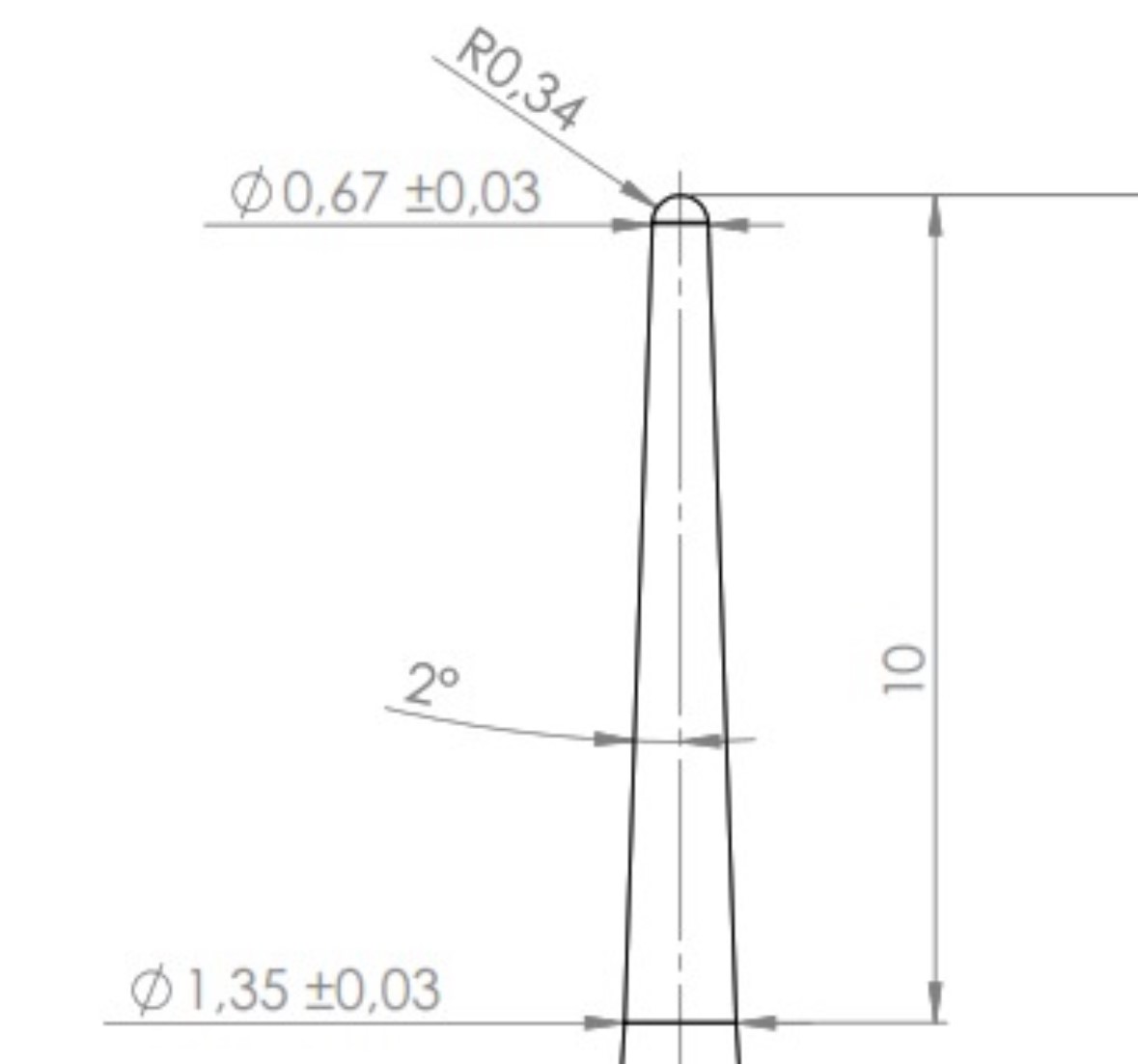

What do you like about the surgical burs?

Primarily the quality, but also the support. Paul is so knowledgeable and goes out of his way to help find solutions to any problems we are having.

I only have to mention a problem, for example that my bone reduction burs are making aspects of full arch surgery awkward, and Paul is able to offer a range of options.

His technical knowledge about his range is excellent, and he goes above and beyond to research anything that he does not have a solution for off the top of his head.

What do you like about the Zirconia adjusting/polishing kit?

I can adjust implant restorations and polish them to a laboratory standard without sending them away, which suits me and my patients!

Previously I would have had to send a restoration back to the lab for reglazing following minor adjustments. That would add a couple of weeks and an additional visit at the detriment of my patients.

Not to mention the lost surgery time for the practice! Definitely a win-win.

How do you find the quality of the burs in general?

Excellent. They are sharper, last longer and generally perform better than any other Burs I’ve used. And we haven’t had to send handpieces off for repair because no one is leaning on them to make up for blunt or inefficient Burs! It’s very difficult to describe the difference that excellent burs make to a procedure.

You have to use them to fully appreciate the impact but it’s not an exaggeration to say that the shift to Crown Dental Burs for our practice was the equivalent of going from wooden wheels to rubber tyres on a car.

Longevity is a massive added bonus, and when you look at the slight increase in spend (versus the cheapest available) and the massive increase in longevity and efficacy, this is a no brainer.

How are you finding the Rota System?

Great. The nursing team now consistently provide me with exactly what I need – and all of the associates feel exactly the same way.

We are all about protocols and processes as they avoid mistakes and improve efficiency and this has made such a difference to the sterilisation process, ordering process and surgery experience for our whole team. Each clinician has a set of burs that are standardised to them.

They receive the same burs in the same order every time and we have replacements in stock but are able to efficiently manage our stock to minimise waste.

I am the course director of the newly launched Transformative Education in Dentistry (TED) which provides implant courses.

TED is proud to work with Crown Dental Burs Ltd and thankful for the support in the upcoming Sinus Tap Course.

We have been very careful about only working with companies who share our ethos of quality of products and support, putting patients first, striving for improvement and genuinely trying to make a difference.

We’re proud to be providing each delegate on our upcoming ‘Sinus Tap Course’ with the full range of burs that are in my Rota System from Crown Dental Burs.

We are excited for the revolution in dentistry that these burs are instigating!

For more information, visit www.staging.crowndentalburs.co.uk.